GGD Series

Low-voltage Power Distribution Cabinet

Introduction

GGD Series Low-voltage Power Distribution Cabinet (PDC,or Power Distribution Unit, PDU) is suitable for power distribution systems with a voltage of 380VAC (50Hz) and a current of 3150A. GGD series has the advantages of high breaking capacity, good dynamic and thermal stability, flexible electrical scheme, convenient combination, strong practicability, novel structure and high protection level. GGD series can convert, distribute and control the power, the lighting, and the electrical energy of power distribution equipment. GGD series are mainly used in power plants, substations and industrial and mining enterprises.

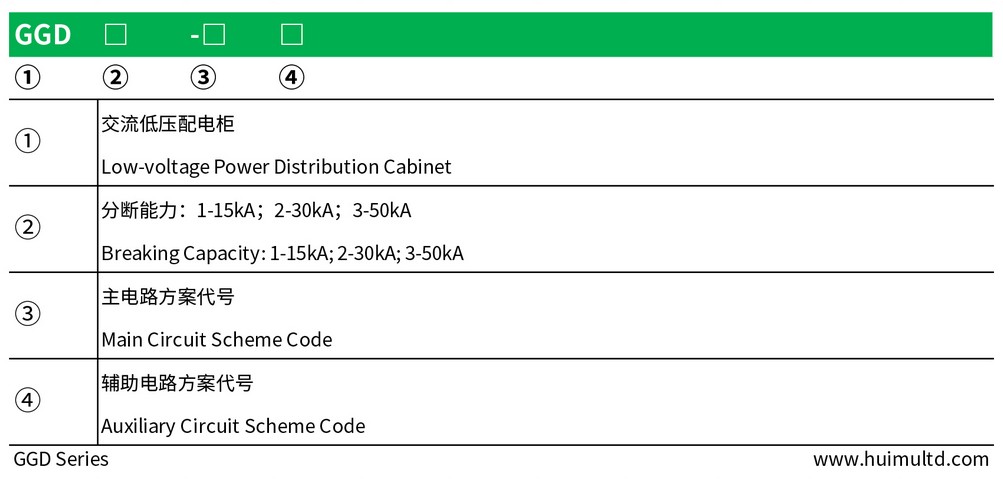

How to order

Features

1. Main circuit scheme

We have designed 129 schemes with a total of 298 specifications for main circuit (not including schemes and specifications derived from changes in the function of the auxiliary circuit and changes in the control voltage), as shown below:

GGD1: 49 schemes 123 specifications; GGD2: 53 schemes 107 specifications; GGD3: 27 schemes and 68 specifications.

2. Auxiliary circuit scheme

The auxiliary circuit schemes can be divided into: power supply scheme and power plant scheme. There is enough space in the GGD cabinet to install secondary components. At the same time, we have also developed a special LMZ3D current transformer to meet the needs of power plants and special applications when additional relay protection is set.

3.Main bus specifications

When the rated current is 1500A and below, a copper single-row bus (or an aluminum single-row bus with the same carrying capacity) can be used; and when the rated current is greater than 1500A, a copper double-row bus can be used. The lap surface of the bus bar should be treated with the tin-coating process.

4.Selection of electrical components

4.1 The GGD cabinet mainly uses advanced electrical components instead of obsolete products.

4.2 HD13BX and HS13BX rotary operation knife switch is a special component designed to meet the needs of the unique structure of the GGD cabinet. It changes the operation mode of the mechanism and retains the advantages of the old product. It is a practical new type of electrical component.

4.3 The internal space of the GGD cabinet has good installation flexibility, and generally will not cause manufacturing and installation difficulties due to updating electrical components.

4.4 In order to further improve the dynamic stability of the main circuit, we designed a special ZMJ type combined bus bar clamp and insulating support component. The bus bar clamp is made of high-strength, high flame-retardant PPO alloy material, and has the advantages of high insulation strength, good self-extinguishing performance, and unique structure. It can be easily combined into a single bus bar clamp or double bus bar clamp by adjusting the building block. The insulating support component adopts a cylindrical molded structure, which has the advantages of low cost and high strength, and solves the defect of insufficient creepage distance of old products.

Application environment

● Ambient temperature: -5℃~+40℃, the average value of 24h does not exceed +35℃;

● Altitude: ≤2000m;

● Relative humidity: monthly average ≤90% (the average temperature of the month is +25℃); relative humidity ≤50% (when the ambient temperature is +40℃). The relative humidity is related to the ambient temperature. The lower the ambient temperature, the higher the allowable relative humidity. For condensation caused by temperature changes, take appropriate protective measures (such as adding drainage holes);

● Installation site: no severe impact, no serious pollution and chemical corrosion, no conductive dust or explosion hazard. And the vertical inclination of the circuit breaker cannot exceed 5° .

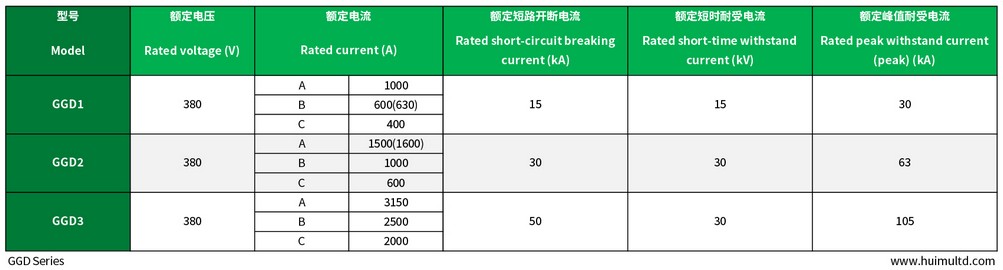

Technical data-sheet

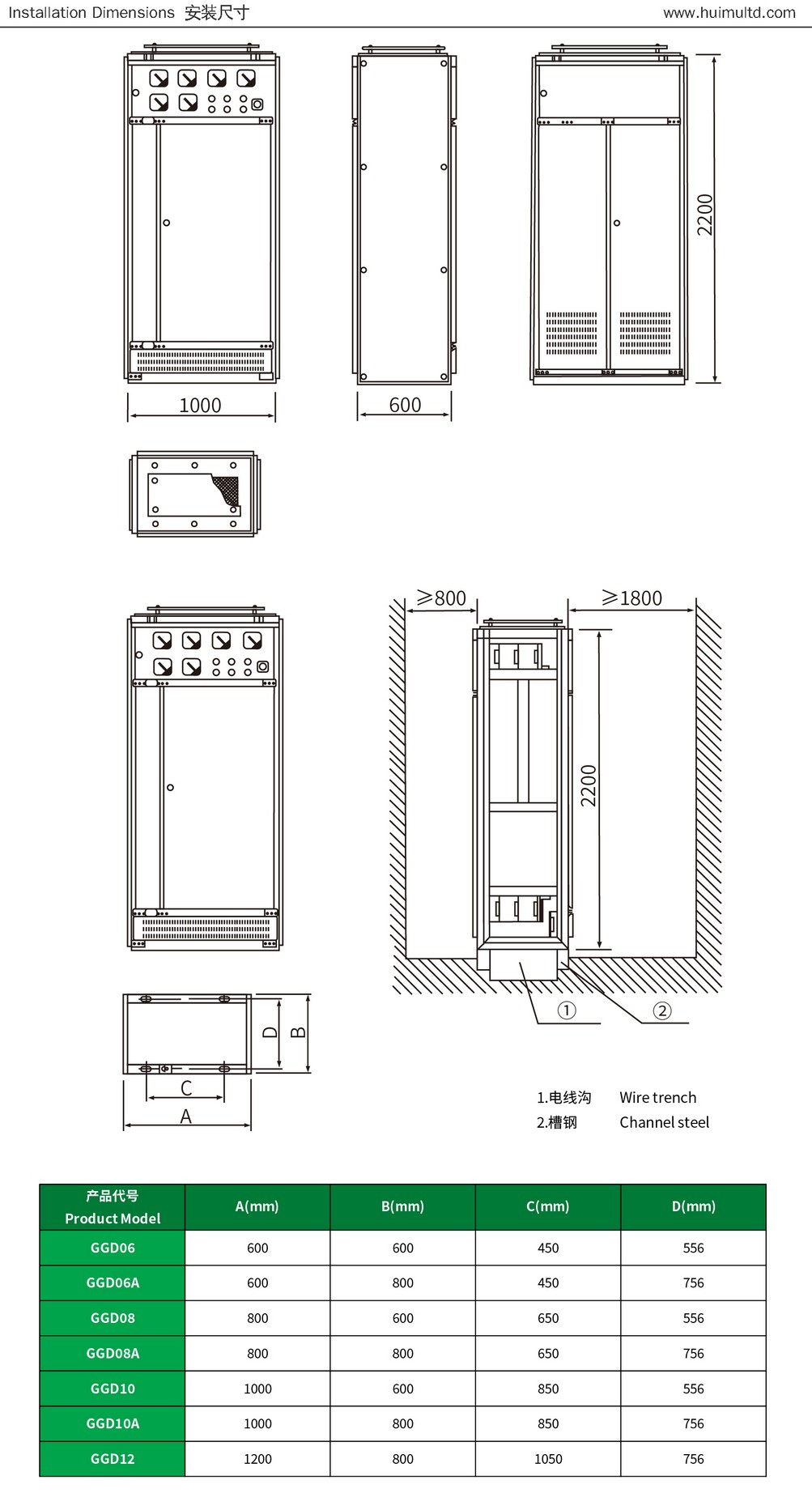

Appearance and mounting dimensions

Attentions

When shipping, we will provide the following documents and attachments:

- Packing list

- Product qualification certificate

- Instructions for use

- Factory test report

- Related electrical drawings

- Cabinet door keys, operating handles and the equipment specified in the contract.

Before installing the product:

- Please check whether the packaging is intact and undamaged, and notify relevant personnel in time if there is any problem;

- Please place the product in an appropriate place for installation. This product cannot be installed against the wall;

- Please install according to the installation diagram. The foundation channel steel and bolts should be prepared by yourself.

Before using the product:

- Please check whether the surface paint of the cabinet is peeled off, and whether the cabinet is dry and clean;

- Please check whether the operating mechanism of electrical components is flexible, whether there is jamming or excessive operating force;

- Please check whether the on-off of the contacts of the electrical components is accurate and reliable;

- Please check whether the transformation ratio and polarity of the indicator and the transformer are correct;

- Please check if the bus connection is good;

- Please check whether the insulation support, installation parts and accessories are firmly installed;

- Please check whether the auxiliary contact meets the requirements, whether the fuse core specifications of the fuse are correct, whether the setting value of the relay meets the design requirements, and whether the action of the relay is reliable and accurate;

- Please check whether the contacts of the circuit meet the requirements of the electrical schematic diagram;

- Please check whether the protection circuit system meets the requirements;

- Please use a 500 volt megger to measure whether the insulation resistance value is higher than 1MΩ.

When using and repairing the product:

- After many opening and closing operations, the main contacts of the air circuit breaker will produce carbonized substances due to local burns, which will increase the contact resistance, so the air circuit breaker should be maintained and overhauled regularly;

- Only professionals with operating qualifications can enter or open the maintenance channels and cabinet doors of the product for operation, inspection and maintenance.

Get in touch with us now!

Please take a minute or two to complete this simple form to get reply in 24 hours, thank you!

*Please check the trash box of your mailbox, if you do not receive our email.